In the era of costs of energy constantly going up the issue of its alternative sources arises. Perspectively thinking, it is impossible to disagree with the opinion that the devices that enable us to save energy are worth investing in which comes along with the reduction of company’s expenses.

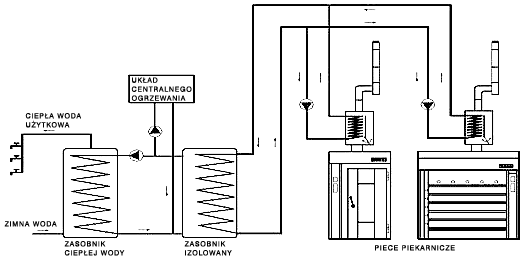

In bakery establishments one of the alternative is heat recycling based on fumes from baking stoves, the efficiency of which is around 85 %. This can be done by reducing the temperature of fumes from every stove. It is possibile to receive 15 % of the energy delivered. The heat of fumes with temperature up to 300˚ C, usually lost, is possibile of being retrieved and used again. The chimney exchanger installed in the chimney canal allows to recycle heat from the fumes without any negative impact on a stove functioning. In this way it retrieves the energy hithereto irretrievably lost. Next, depending on the needs it is possibile to use it to heat running water, for central heating or other purposes. The device is safe, economical and practically self-catering.

The size of an exchanger is individually chosen according to the size of a baking stove, in this respect the heat retrieval is appropriate according to the size and degree of a stove utilisation within a day.

Exchanger – both the casing and the coil are made of stainless steel and welded as awhole, which all enables to avoid leaks or cracks. The construction of the exchanger allows to omit the coil in the case of extensive water accumulator heating, overheating of the installation or any defect. In this case the fumes are automatically transported through an additional canal that omits the exchanger element. The whole installation is checked by an infallible autoprotection and autocontrol.

The configuration consists of:

- exchanger (or a few exchangers),

- installation with a circular pump,

- automatic control,

- hot water accumulator.

The parametres of a configuration are individually chosen according to the establishment size.

Water accumulators with one or two spiral coils are used to generate hot water. They may cooparate with one or several exchangers, central heating installation. The container is made of a sheet of steel covered with a layer of ceramic varnish. Another rust protection is the magnetic anode which undergoes periodic control. The container is insulated with polystyrene foam which limits the heat loss to the maximum and it also keeps high temperature of water in the exchanger long time after turning off the power supply. Additionally, insulation is built in in the metal casing.

The investment made in purchasing the heat recycling installation pays back in a short period of time and it guarantees additional, free and efficient source of energy in a manufacture.